Blasting Mats for Road Cutting & Drilling

What would the United States be without the infrastructure that connects neighborhood to neighborhood, city to city and state to state? Road cutting is an essential part of developing that infrastructure.

Each year, roads are cut around the world using blasting methods, which removes hard rock from beneath the planned roadway’s surface. The rock blasting process is controlled, of course, but there are always safety concerns when creating an explosion.

Blast mats are important tools for road cutting because they are what control the actual explosion. These road cutting tools help keep people and equipment safe as the rock blast procedure moves forward. Read on to learn more about blasting mats for road cutting and how they are a huge part of safe drilling and blasting techniques.

Blasting for Road Expansion and Construction

Think about all the geographic features that make it difficult for roads to be constructed, such as mountains, valleys and hills. Each of these features can make it difficult to build a roadway where it needs to be.

Through road blasting, construction teams can actually cut through mountains, level valleys or even reduce hill heights to build or expand a road. The rock blasting procedure is designed to also ensure the area is level for road construction after the blast. In some cases, teams create embankments by reusing cut material.

Contact Us

Of course, no two road construction blasting jobs are exactly the same, and engineers rely on several different blasting methods to shape and prepare different types of roads. Those methods include:

- Pre-split blasting: Holes are drilled farther apart and loaded lightly in this lighter form of explosion.

- Mass rock blasting: This is a much heavier form of blasting used to initially clear the largest impediments.

- Trench blasting: Trench blasting is often used to create space for pipes and rain drainage lines below surface level.

- Precision blasting: If mass rock blasting is used initially to clear the largest impediments, precision blasting is used later in the process to clear smaller areas.

Teams choose which techniques and rock blasting equipment to use based on each project’s unique factors, such as the scale of the project and its proximity to roadways, homes and businesses. The type of rock also influences the drilling patterns and explosives used in each method.

Road-Cutting Projects

Road-cutting projects take place across the country and around the world. Anytime a road needs to be built through a challenging environment, road-cutting equipment and processes are used to get the job done.

The Pikeville Cut-Through in Kentucky on U.S. Route 23 is just one good example of road cutting in action. The Sideling Hill Cut on Interstate 68 is another.

More recently, road-cutting projects in the United States include the Snoqualmie Pass in Washington where I-90 passes through, U.S. Route 26 near Mount Hood in Oregon and State Route 77 in Arizona. With each of these projects, road cutting was used to either expand road lanes or to remove rock that could have potentially fallen on the roadways.

Around the world, road cutting is used in places like Africa, Asia and Latin America — any place that needs to grow its infrastructure but that also needs to drill and blast to flatten space for roadways

Equipment Needed for Road Cutting

Road cutting requires all manner of equipment. Naturally, teams need drills and other equipment for creating the holes where explosives are laid. They also need the actual explosives themselves. But the most important equipment for road cutting is blast mats — because blast mats help keep everyone and everything in the vicinity safe and secure while blasting is taking place. They provide protection from projectiles, like flyrock, which ensures your team and any bystanders remain unharmed from the explosion. Protection is crucial, as road blasting can occur near homes and businesses that straddle the existing roadway.

Road cutting requires all manner of equipment. Naturally, teams need drills and other equipment for creating the holes where explosives are laid. They also need the actual explosives themselves. But the most important equipment for road cutting is blast mats — because blast mats help keep everyone and everything in the vicinity safe and secure while blasting is taking place. They provide protection from projectiles, like flyrock, which ensures your team and any bystanders remain unharmed from the explosion. Protection is crucial, as road blasting can occur near homes and businesses that straddle the existing roadway.

Blast Mats for Road Cutting

Blasting mats for road cutting do not need to be expensive. In fact, Mazzella Blasting Mats are made using recycled material, and they are sold without a middleman — meaning attractive prices and long-term value. Mazzella Blasting Mats can also be used over and over again, which also helps you get more for your money.

Blasting mats for road cutting do not need to be expensive. In fact, Mazzella Blasting Mats are made using recycled material, and they are sold without a middleman — meaning attractive prices and long-term value. Mazzella Blasting Mats can also be used over and over again, which also helps you get more for your money.

How are blast mats used in road cutting? They are essentially control devices that can be placed anywhere debris might emerge during or after blasting. They are also available in a wide range of sizes, so you can always find the perfect blasting mat for the space you need to secure.

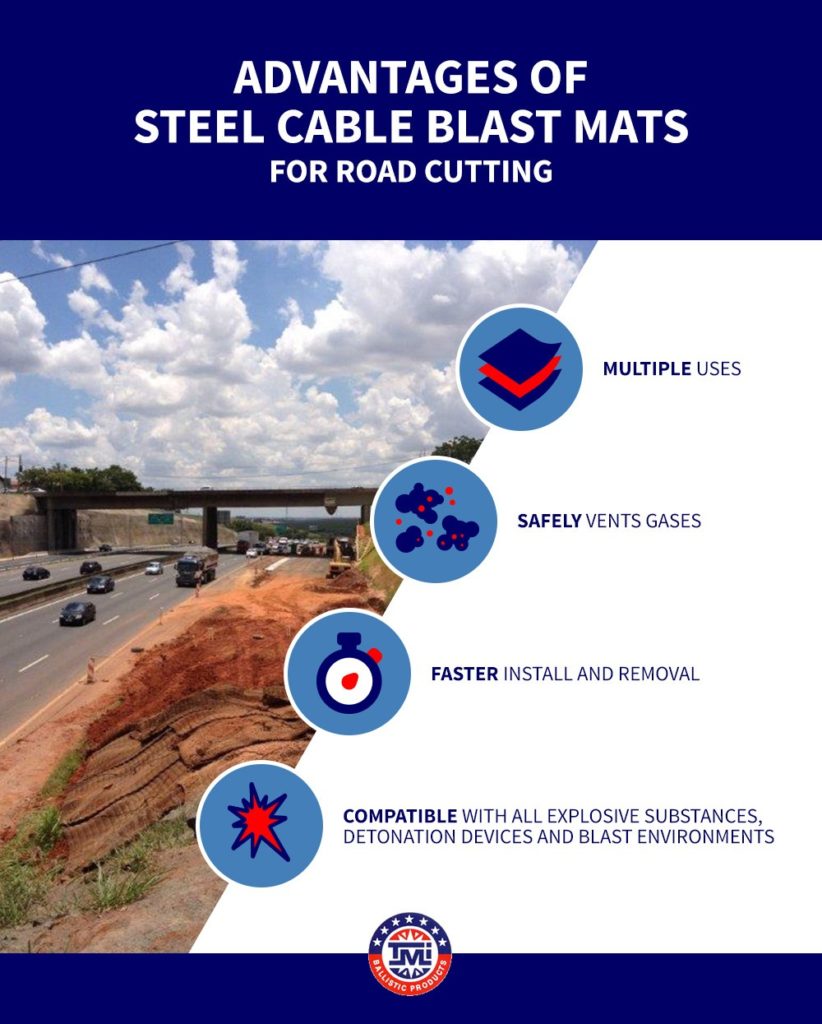

Our steel cable blast mats for road cutting provide a series of unique benefits that distinguish them from traditional rubber mats. These advantages include:

- Multiple uses

- Safely vents gases

- Faster install and removal

- Compatible with all explosive substances, detonation devices and blast environments

Get Your Blasting Mats for Road Cutting Today

Selecting our blast mats for your road cutting projects allows you to save money, stay safe and remain productive on your blasting assignments. Contact us today to learn more about road cutting equipment like blasting mats, or to get more information on pricing.