Chemical plants can be dangerous places to work. Employees commonly have to handle substances capable of inflicting multiple types of harm, from burns to combustion. These chemicals aren't just harmful at the individual level. Large quantities of chemicals can explode in facilities, damaging equipment and workers alike.

In response to these explosions, many facility managers are seeking ways to improve chemical plant safety. If you're among these individuals, you'll be glad to hear there are several methods for doing so. To make your prevention efforts effective, you need to have an understanding of what causes explosions to start with, as well as what their consequences can be.

What Causes Chemical Plant Explosions?

It goes without saying that explosions are something you want to avoid. But why do chemical plants explode in the first place? The answer comes down to a combination of two factors — a chemical's properties and its environment. Chemical properties relate to what the chemical is. Certain types of chemicals are naturally combustible, and that requires careful handling.

This is where environment comes into play. If a chemical is combustible, it's imperative to monitor how it's handled and what it comes into contact with, as either one could potentially ignite it. Here we'll look at some of the most common causes of chemical explosions.

1. Equipment Failure

In petrochemical facilities, chemicals are frequently processed and handled by different types of machinery, such as boilers. Machinery is prone to all sorts of issues. Whether a piece of equipment springs a leak or overheats, the smallest mistake can be enough to ignite the chemicals inside and cause an explosion.

In many cases, this situation is hard to prevent. Equipment can be unpredictable — particularly when it gets old, as happened at one facility in Anacortes, Washington. Sometimes, malfunctions occur because the machinery wasn't properly installed or maintained. Without occasional inspections and repairs, equipment failure becomes almost inevitable.

2. Lack of Training

If the error doesn't stem from the machinery, it may stem from the people operating it. It's easy to take for granted that everyone working in these facilities are knowledgeable professionals, but all those workers were new to the job at some point. New employees must receive the proper training, or else they may not have the knowledge they need to do their job properly years down the road.

When employees aren't trained as fully as they should be, it is easy for them to make mistakes without even realizing it. If someone doesn't turn off a machine at the necessary time or wear the proper safety gear, they put themselves and everyone around them at risk.

3. Impure Chemicals

Chemicals undergo various processes in facilities, and these processes function in particular ways. For a process to work, it relies on the chemicals having a particular set of properties. If those properties were to be changed, the process might react differently with the chemicals, possibly with destructive results.

That's exactly what can happen when chemicals become contaminated. If another substance is mixed with a certain type of chemical, it will be subjected to each process the chemical goes through. Most likely, the process wasn't designed to handle a contaminant substance.

The resulting unplanned reaction can sometimes cause explosions, such as the one that happened in Atchison, Kansas, when two incompatible chemicals were mixed together.

4. Corrosion

Sometimes your equipment will stop being able to do its job correctly because it's being torn apart from the inside. Various types of chemical buildup, particularly those involving acids, can cause metal corrosion.

In these cases, the chemicals will eat away at the metal parts in your equipment, rendering them unable to function properly. Corrosion can cause equipment to break down midway through processing combustible chemicals, which does not end well.

5. Combustible Dust

It's one thing to be careful around chemicals when they're kept in solid or liquid form within metal containers. But what about the chemicals in the air? Processing plants are filled with dust and gases given off by chemicals, metal parts and more. This dust is highly combustible, and something as small as a spark can set it off.

Combustible dust is tough to guard against, so the best approach is to prevent open sparks or flames wherever possible.

6. Water and Soil

The air isn't the only area that can become contaminated. Water and soil often carry their own combustible contaminants. Well water, for instance, frequently carries concentrations of methane, which can ignite once released into the air. This release isn't a large concern in most cases, but when you're surrounded by highly combustible chemicals, it's a significant danger.

7. Safety Violations

As unfortunate as it may be, many plants fail to adhere to safety regulations laid out by organizations like the Occupational Safety and Health Administration (OSHA). This failure could entail placing chemicals too close together or failing to distribute proper safety gear. In an explosion in DeRidder, Louisiana, it was because workers were performing heat-emitting activities near a highly flammable tank.

Safety violations may be executed for the sake of convenience, or from a mentality of "It's okay, we'll be careful," but the consequences can be devastating. However inconvenient some of the regulations may seem at times, safety regulations are there for a reason.

What Happens If a Chemical Plant Explodes?

It can be hard to imagine just how large scale chemical plant explosions can be. You may picture a small flash in one area of the facility, which is over quickly with no significant impact on most of the plant. This picture may be a reality in some cases.

More often, small explosions quickly trigger larger ones. If one vat of chemicals goes up in flames, those flames can ignite combustible dust in the air, carrying the explosion to other areas of the facility. Within seconds, a chain reaction can take place, and the entire plant can erupt.

The results can be catastrophic. To start with, a plant can be largely destroyed — with all the chemicals and machinery crippled by the explosion. The danger to the workers can be even worse. There can be heavy injuries, ranging from broken limbs to severe burns. At worst, the explosion or injuries can be fatal for workers.

The effects of a chemical plant explosion are not limited to just workers — any residential areas near the plant may be hit too. In one explosion that occurred in West, Texas, 12 firefighters and two members of the public were killed, and hundreds of other people sustained injuries.

With consequences this high, there's no question that steps must be taken to keep these explosions from happening whenever possible. Chemical plants have to do what it takes to keep their premises safe.

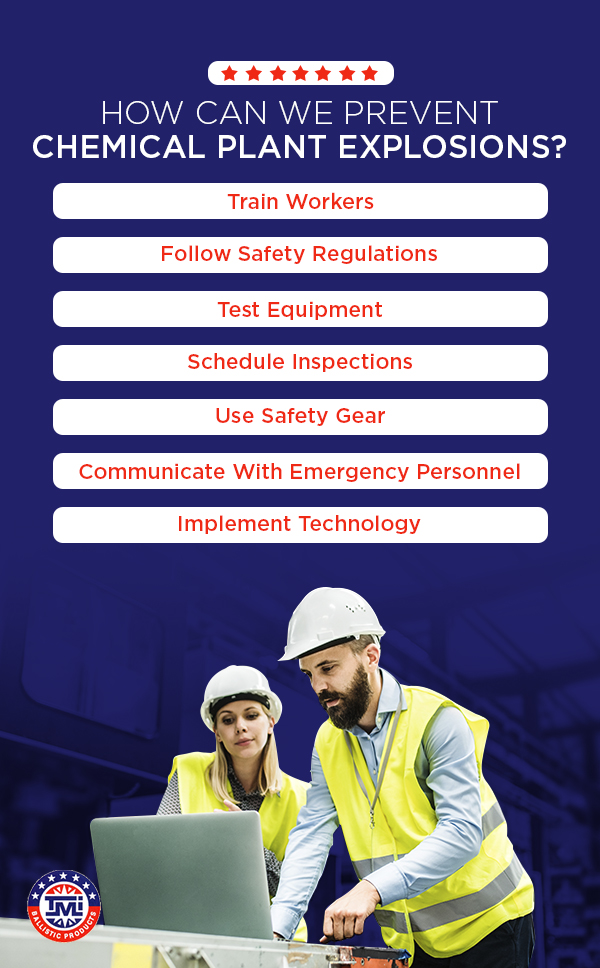

How Can We Prevent Chemical Plant Explosions?

With this goal in mind, what safety precautions should be taken to prevent future chemical plant explosions? Prevention starts with recognizing the severity of the situation and the different ways it can go wrong. Then, something has to be implemented to address those issues. Fortunately, chemical plants have several options available to them. Here are some of the best practices for how to prevent chemical plant explosions.

1. Train Workers

Your precautions should start with something as simple as making sure your workers know what they're doing. When you bring on new employees, provide extensive training to make sure they understand how to operate all equipment and follow safety guidelines. You should also consider implementing continuous training, where even senior workers are reminded how to perform different procedures.

The more frequently these refreshers occur, the better. It may not be beneficial to have employees reread an old manual page once a year. Conduct the reviews on a weekly — or at least monthly — basis, and make sure you give the workers a chance to show they know how to do the tasks the right way.

2. Follow Safety Regulations

Make certain you and all your employees are following all OSHA regulations and other safety guidelines. You can train workers on what they should do, but if you have people deliberately disregarding that training, none of it matters.

This process mainly comes down to having a healthy amount of self-accountability and oversight. Hold yourself to a high standard, and make sure your workers feel like you're holding them to that standard as well.

3. Test Equipment

As previously noted, equipment can prove faulty for many reasons. Malfunctions, corrosion and poor maintenance can all contribute to a piece of machinery's demise. While it's impossible to predict every malfunction perfectly, you can minimize the number of potential problems by regularly testing and inspecting equipment.

Be aware of the various places things can go wrong, and keep a close eye on each of them. If there's a spot that's prone to produce sparks, put up something to block them from coming into contact with chemicals. If there's an area that's particularly vulnerable to corrosion, clean it frequently.

4. Schedule Inspections

While you can do a lot of good by keeping an eye on your workers and equipment, you may still be prone to overlook things when you're working in the same environment day after day. It's helpful to bring in a fresh pair of eyes occasionally to catch those oversights. Organizations such as OSHA will often provide these inspections, giving you insight into where you may have safety issues.

The deadliness of explosions makes chemical plants a top priority for OSHA. Inspections can also be good for your image and conscience if something still goes wrong down the line, since your choice to schedule the inspection can validate the accident wasn't due to your negligence.

5. Use Safety Gear

Look for the biggest hazards to your workers in the facility, and try to implement the best safety gear to guard against those hazards. Consider what might protect them if they were near an explosion. In general, the more of a worker's body that is covered, the safer they'll be.

6. Communicate With Emergency Personnel

If an explosion does happen, emergency workers such as firemen will need to be called in to deal with the problem. They won't be facing a normal fire, though — with so many chemicals involved, the emergency personnel will have to know what they're dealing with.

You can speed up this process by preparing ahead of time. Contact local emergency workers about what your facility does, and keep them updated on which chemicals are housed there. Doing so can make things easier for them if they ever have to be called in later.

7. Implement Technology

You're not limited to working with the materials that normally appear in chemical plants. You can bring in newer technologies that can help you improve the safety of your work environment. Plenty of tools are available for helping prevent or contain explosions.

One example is automatic shutoff valves, which are installed on tank discharge pipes and programmed with a specific temperature limit for the tank. When the limit is exceeded, the valves automatically shut off. These valves, along with the other measures mentioned above, are intended to prevent explosions from happening to start with. Other technologies deal with situations where an explosion happens.

Designing a Blast-Resistant Petrochemical Facility

The ideal situation is one in which no explosions occur, but it's impossible to plan for unexpected situations. For this reason, the best thing you can do to handle the potential for explosions is to take preventative measures. If you can't prevent an explosion, the next best thing you can do is try to contain it, minimizing the amount of destruction it causes. That idea is what underlies the concept of blast-resistant buildings in petrochemical facilities.

Some methods of making your facility blast-resistant relate to structure. You can give your machinery a solid foundation and a sturdy build to help limit how much damage an explosion can do to it. Some of the most effective solutions, however, can be found in technologies like blast walls and barriers. These materials are constructed from tightly woven wire rope that absorbs the impact of an explosion, keeping it from spreading to other areas of the facility.

Blast walls are an excellent means of limiting chain reactions and minimizing the damage and injuries sustained. While explosions will always be destructive, the right technologies can keep them from being catastrophic.

Contact TM International, LLC for Chemical Plant Safety & Blast Mitigation Solutions

If you're looking for blast mitigation equipment for your facility, TM International, LLC has you covered. We offer top-quality blast walls and walls that are easy to transport and install. These barriers can limit peak blast pressure by up to 80% while simultaneously venting toxic fumes and gases.

To start equipping your petrochemical facility for maximum explosion safety today, get in touch with us and tell us about your needs.